IMS HS3

- Necker

Optimize can plant productivity by integrating the Belvac Intelligent Manufacturing System (IMS) and the High Speed Selective Sorter (HS3) into your necking systems.

Key Benefits

By integrating Belvac’s Intelligent Manufacturing System and High Speed Selective Sorter into your current necking process, operators can benefit from real-time dynamic monitoring and accurate sampling of plant’s processes and products. This results in improved production efficiencies, increased accuracy of quality control, and reduced downtime for sampling and troubleshooting.

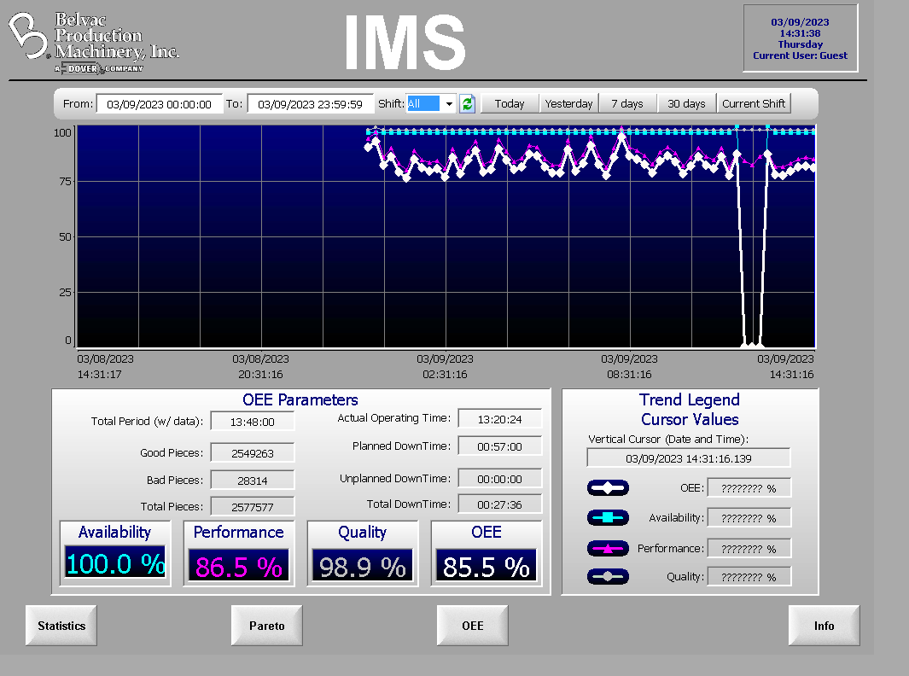

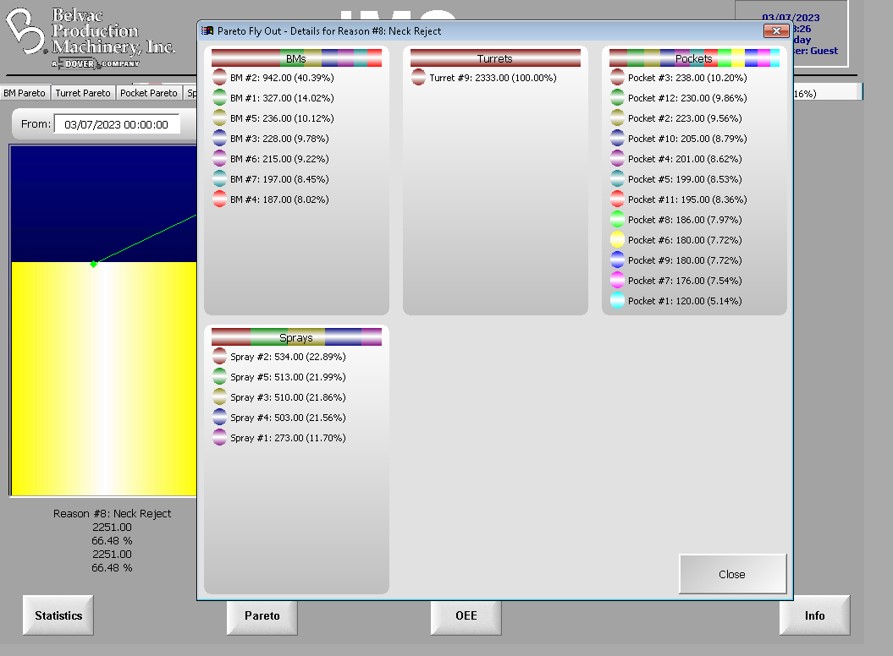

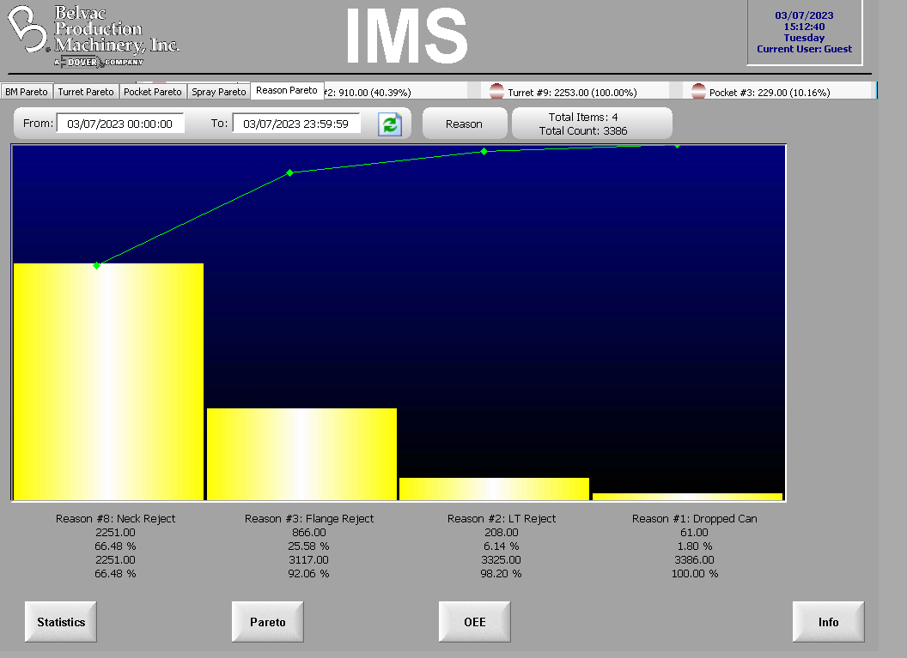

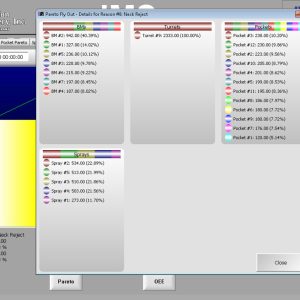

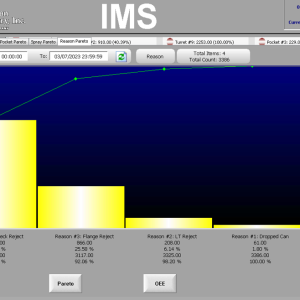

Intelligent Manufacturing System (IMS)

The IMS is a combination of hardware and software that works in tandem with the Necker to group and prioritize vision system defects, helping to locate the root cause of spoilage. This system provides dynamic quality control by tracking and storing important reject data, allowing for more efficient troubleshooting of issue including those from front-end machinery.

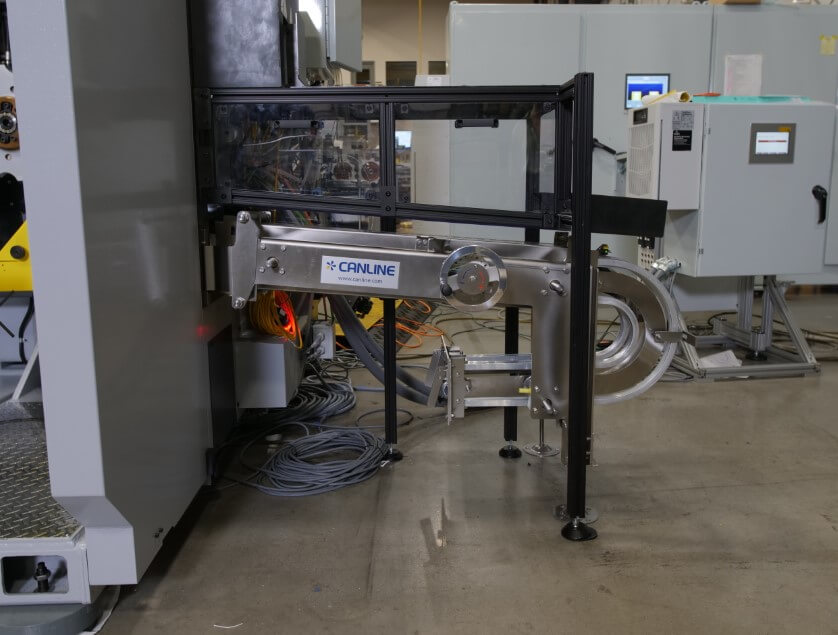

High Speed Selective Sorter (HS3)

The Hs3 enables sampling and sorting without interrupting normal production speeds, providing operators more freedom in configuring sample selection. The system also allows for repeated schedules and routine sampling which can be configured through the operator interface and stored for later use. Plant Supervisory Control and Data Acquisition (SCADA) can be accessed remotely to configure sample requests based on QA scheduling and process-driven quality sampling requirements.