Bottle Container Manufacturing System

- Bottle Can Machinery

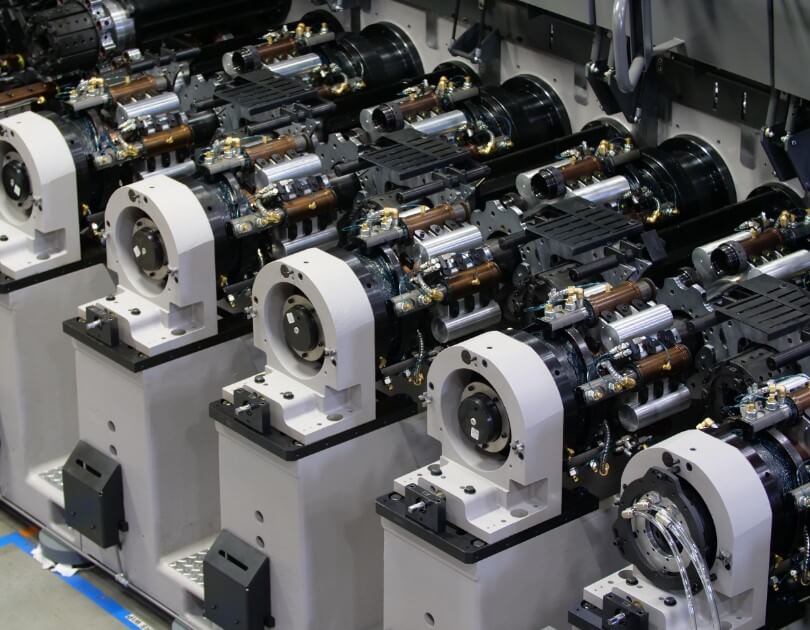

The Bottle Container Manufacturing System is designed to produce the lightest weight specialty container at high speeds.

Key Benefits

The Bottle Container Manufacturing System (BCMS) is the perfect solution for high-speed, high-volume, and cost-effective bottle production. This innovative system produces specialty neck configurations for lightweight metal bottles with ROPP and Crown closures, as well as Aerosol with Transfer or Ogival Necks. With the BCMS, speeds of up to 600 bpm can be achieved, all while reducing the overall machine footprint.

How It Works

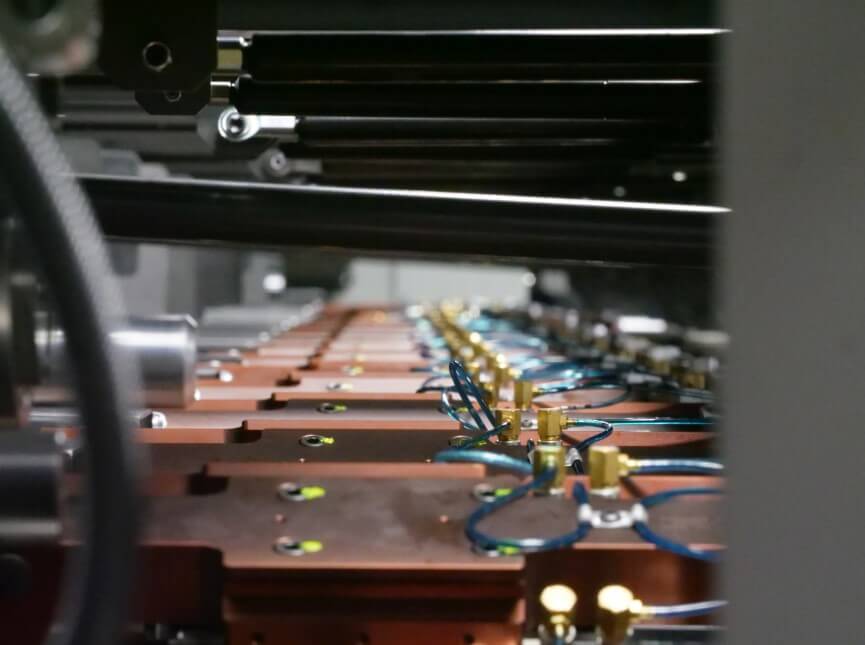

Using the BCMS’s state-of-the-art technology, the preform containers are lubricated and fed into the odd pockets on each turret. From there, they undergo a series of progressive necking operations, including trimming stages until they reach the threader. The first pass necked preforms are then recirculated back through the second infeed, ensuring pocket-to-pocket integrity through each process turret.

The advanced patent forming technology can create a Roll on Pilfer Band (ROPB) groove on a single module versus the traditional neck and expansions processes, eliminating the need for expansion cameras and blow-off. This results in less wear parts, loss of process air, and lower spoilage, making the BCMS the optimal solution for your production needs.

Belvac Carrier Ring

Transitioning from PET to aluminum is costly.

That’s why we developed The Belvac Carrier Ring, allowing aluminum bottles to be filled on existing PET filling lines. This is the future of sustainable packaging, making the transition to 100% recyclable packaging that much simpler.

Sustainability, it has a Ring to it.