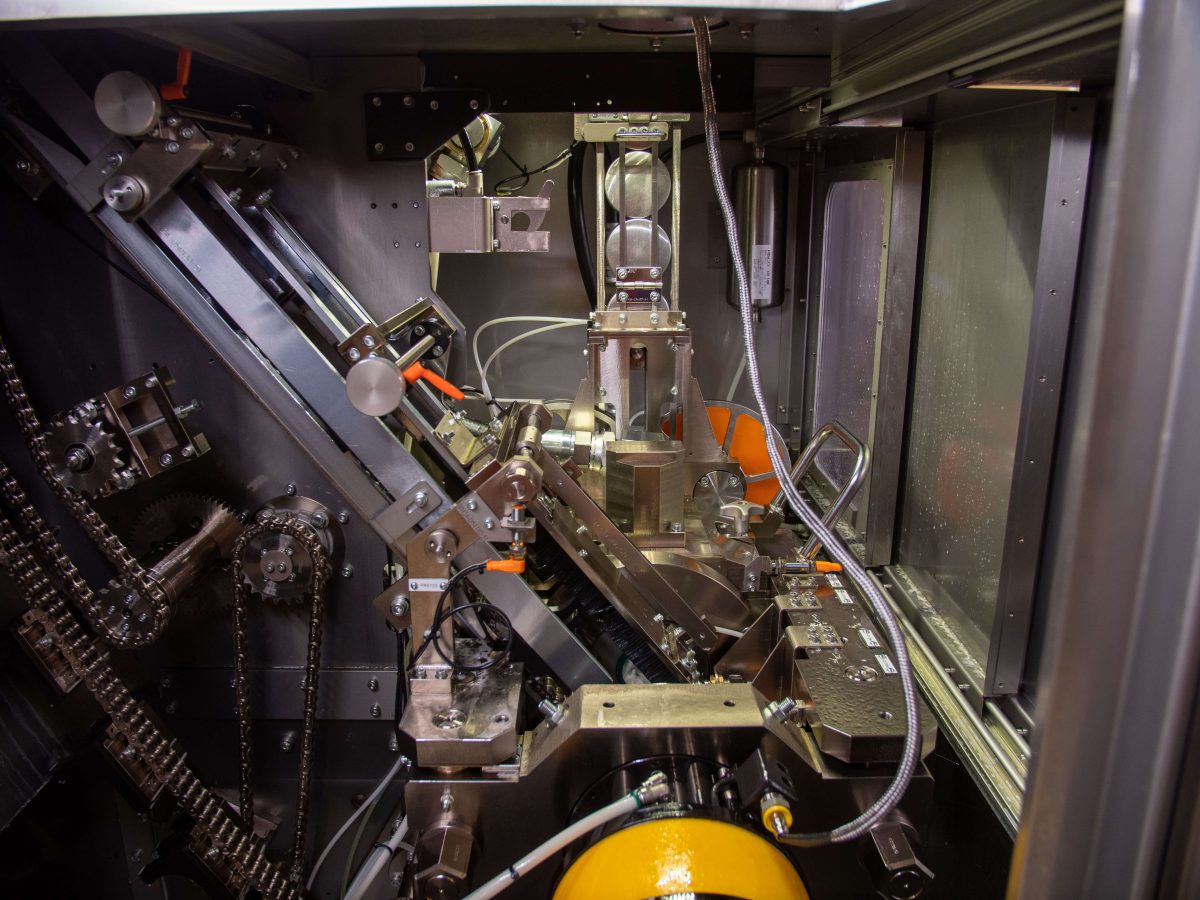

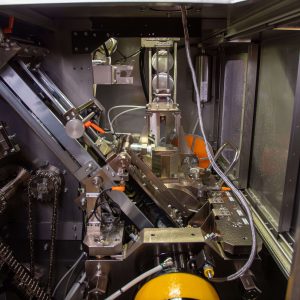

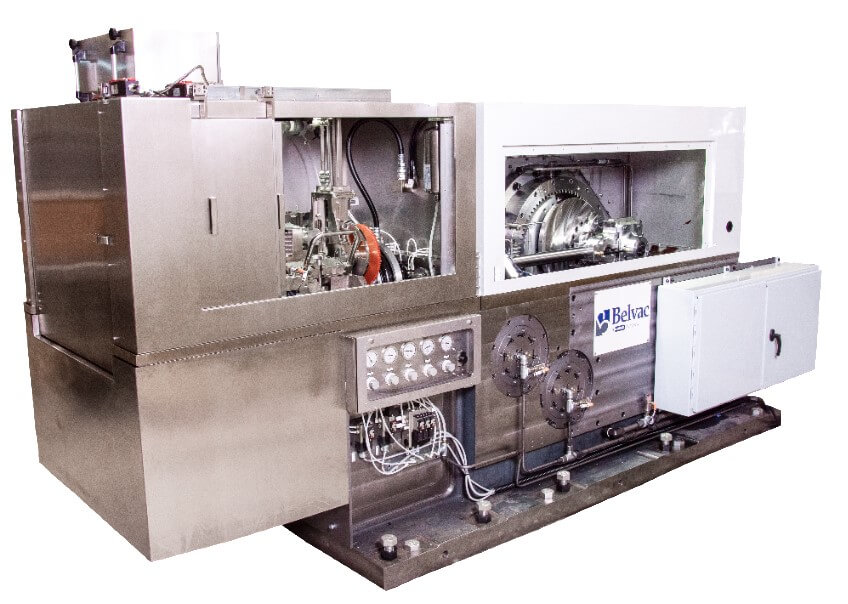

Bodymaker

- Can Making Machinery

Utilizing a hypocycloid main drive the Belvac Bodymaker produces superior can quality with low tear-off rates, continuously operating up to 400 cpm.

Key Benefits

The Belvac Bodymaker is the ultimate solution for all your can making needs. It’s designed to be compact, efficient and reliable, operating continuously up to 400 cpm. Unlike other models, this Bodymaker features low vibration, and utilizes hypocycloid main drive which features no vertical movements resulting in no foundation requirements. With superior can quality, marked by low tear-off rates and accurate body wall thickness, the Belvac Bodymaker produces the highest level of can quality.

Equipped with many features that facilitate low maintenance and reduced oil consumption, meaning minimal downtime, the Belvac Bodymaker is the optimal choice for canmakers. Additionally, the Bodymaker has an increased ironing die life, which adds value and reduces replacement-related maintenance costs and downtime. Choose the Belvac Bodymaker to streamline your can making process and improve your business’s bottom line.