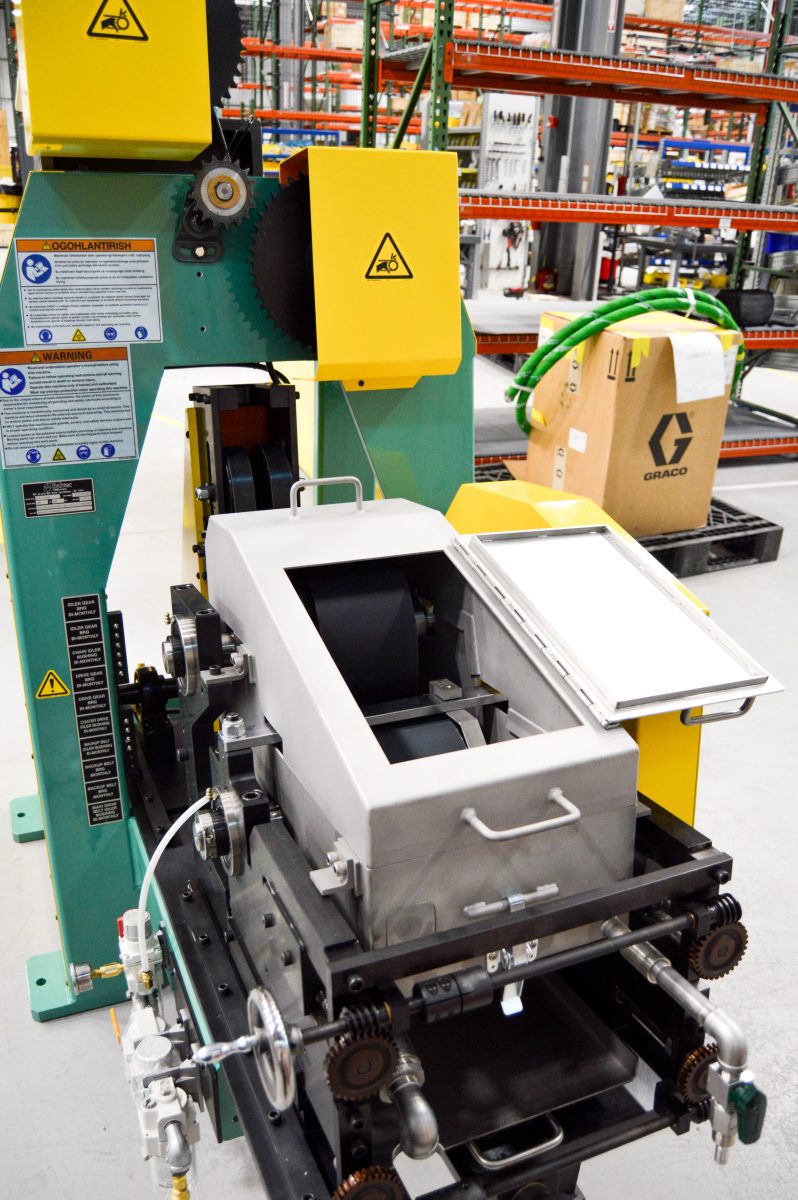

Bottom Rim Coater

- Can Making Machinery

The BV86 Bottom Rim Coater applies a wear-resistant coating, that facilitates superior protection to the can’s bottom rim surface.

Key Benefits

The inherently sticky surface of the can domes makes bottom rim coating a necessary step after the can washing process. The BV86 Bottom Rim Coater applies a wear-resistant coating that facilitates superior protection to the can’s bottom rim surface, which is integral for smooth can handling and processing. Allowing for better can transfer to conveyance systems and machine infeeds, the coating also help prevent tipping during the filling process and protects can integrity during the packing process when external leaks occur.

The BV86 Bottom Rim Coater features two configurations: (1) bottom drive units for floor installations, and (2) Mezzanine Mount or “Top Drive”. Both configurations utilize the pin chain’s power supply. The top drive configuration, designed for mezzanine installation, runs at 2,400 cpm. The bottom drive configuration is available in either a 96-tooth or a 126-tooth sprocket, which runs at 1,800 and 2,000 respectively.

The gravure roll efficiently coats the bottom rim with varnish while minimizing excess varnish runoff. Urethane sleeve applicators are used and able to be easily replaced requiring minimized downtime. The doctor bar, fitted against the roller, wipes the excess varnish from the roller ensuring minimized product use. Different doctor bar blade sizes are available to easily be changed out for different varnish types. The BV86 is suited for solvent, water-based or UV coatings.