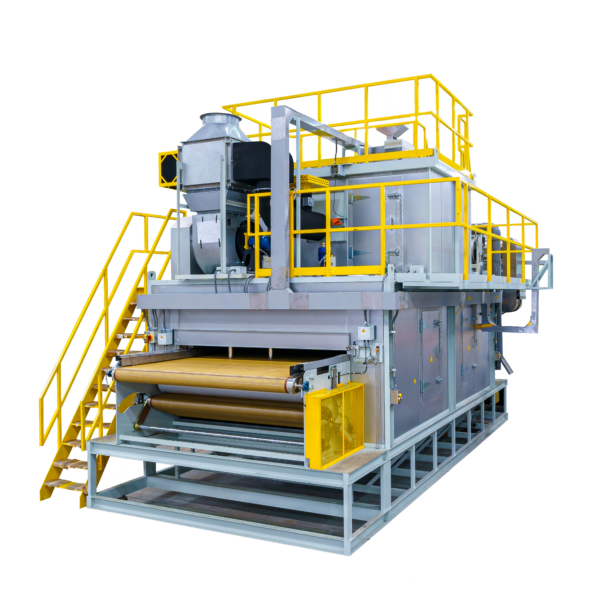

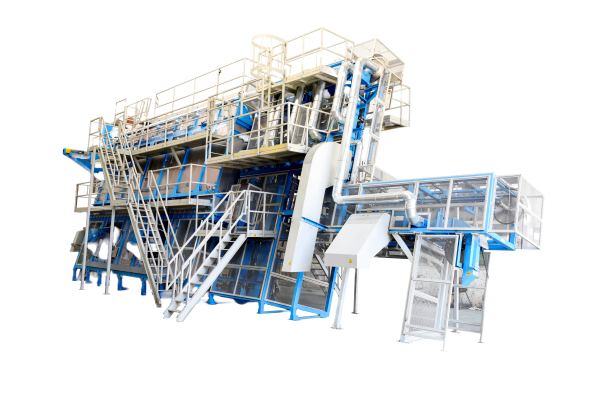

ARC Pacific has kept process and energy efficiency at the forefront of our vision when designing our Can Washer and Oven Systems. By taking a full system approach to the machinery and innovations, we are able to apply integral knowledge that helps increase energy savings and process controls for the Can Washer, Dry-off Oven, Pin-Oven, IBO and Heat Recovery Systems.

With years of experience in the two piece canmaking industry, ARC has identified three major levels for energy saving potential. First is the various design changes aimed to maximize energy efficiency. Second is integrating intelligent operating functions into the equipment, which enables machines to automatically adapt to actual production speeds, achieving maximum savings. Third is to use multiple levels of heat recovering which offer canmakers more sustainable Washing, Drying and Baking processes.

Furthermore, we are able to offer energy saving audits which allows canmakers to quantify their expected savings during operational periods. We are dedicated to providing customers with energy efficient and saving technologies that further reduce energy costs and CO2 emissions.